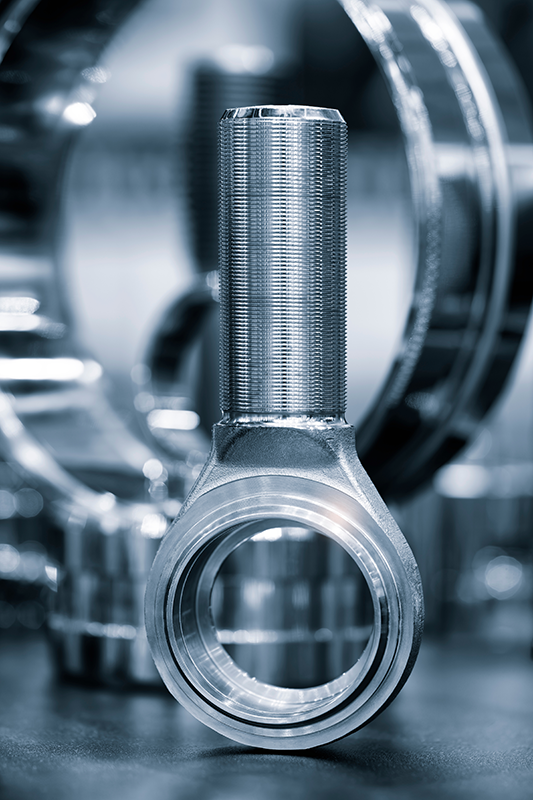

Sophisticated and Flexible

Production Lines

The modern processes and equipment at Three J’s Industries are designed for the following reasons:

- To consistently achieve the requirements of demanding specifications.

- To provide flexibility in the production schedule in order to meet delivery commitments.

- To maintain a clean operation necessary to minimize wastes and emissions.

Any size job from the smallest fastener to the largest stamping can be accommodated. The company has backup items on all equipment to ensure no downtime. A complete machine shop is located on site where equipment can be precisely fabricated and maintained for production.